SVJV udvindes MSG primært ved fermentering af stivelse og sukkeraf forskellig art, så det er allerede plantebaseret.

I have having major issues lately as well using the voyager app. My account on sopuli.xyz is the only one with issues, my alt on another instance works just fine.

It takes a long time to load anything, and comments in posts turn up in my inbox several days delayed.

Hoping you find the cause of this soon 👍

Wow yeah that first one is pretty terrible looking 😅

I'm decently pleased with mine though, but I'm really looking forward to the quality on the voron. I actually already have "the filter" on my current printer (slightly oddly placed in the tent, but it works), and I just connected it directly to the printer PSU and manually turn it on/off with a toggle switch.

Regeringen går virkelig all in på at bruge pisken i stedet for guleroden med stort set alt de foretager sig.

Rasmus Stoklund sætter stadig sin lid til, at regeringens reform kommer til at virke efter hensigten:

Der er jo ikke nogen af os her i studiet, der kan vide, hvad der sker - det er jo en trossag.

Rasmus, du er jo en idiot og burde ikke sidde i en stilling, hvor du kan have indflydelse på hvordan landet styres. Det bør ikke være "tro" som styrer politikeres handlinger, det bør være fakta.

Den er overraskende rummelig når man lægger bagsæderne ned, og med den store firkantede åbning kan man faktisk fragte pænt store ting i den, så længe der maks skal være to i bilen. Og det er et 2:1 split bagsæde, så man kan lægge den ene side ned og have plads til tre personer samtidig med en pæn mængde bagage/gods.

Havde sågar engang en kollega der fik plads til et 70" TV i kassen, med alle døre.og vinduer lukket, i sin up...der var så kun plads til ham, men alligevel, det er ikke dårligt.

Edit: men en corolla er også en god lille bil der er billig at reparere.

Garmin is pretty much gold standard when it comes to sports tracking. Most other brands are a step down, and I imagine a FOSS watch like the bangle.js is a significant step down from Garmin watches WRT sports tracking.

Hvordan gik det så?

The solution was more cooling. It was warping due to too much heat, I increased cooling to 100% and reduced overhang speed slightly and it now prints well.

Both ASA and ABS are approved materials. ASA has higher heat defection than ABS, should be easier to print and it smells significantly less when printing.

Fans are completely disabled, except for overhangs and bridges. If I disable fans for overhangs and bridges, they sag like crazy.

I doubt draft shield is going to do anything, the printer is already completely enclosed in a tent. I have around 50-55°C inside the tent.

Edit: I tried a re-print with less cooling for overhangs, it seems to exacerbate the issue significantly.

Trouble with ASA prints

[SOLVED] cause: not enough cooling for overhangs

I increased cooling on overhangs from 60% to 100%, and decreased overhang (10-25%) speed from 100% of outer wall speed to 85%. Issue went away completely and it now prints nicely �*

I've started printing parts for my voron 2.4, and it's generally going well enough. The parts are looking pretty decent. But I'm having a hard time getting good results with overhanging sharp corners. They tend to warp upwards as seen in the photo on the left side. The prints stick well enough to the build plate and I don't have any other warping or adhesion issues.

Is this because my cooling for overhangs is too much?

I generally print with no part cooling in an enclosure. Temps are 245°C on the nozzle and 105°C on the bed, using 60° fan speed for overhangs. I'm printing on a anycubic kobra 2 with azurefilm ASA.

Piped isn't working for me either anymore. I was using piped.adminforge.de before, but I've tried other instances too without any luck. It won't load play any videos at all. I can search and find stuff without issues, but I can't play anything.

I just swipe left for "back" (android), and I can access everything just fine, it just closes the TOS. Just do that every time I open the app, works like a charm.

You're just making it worse better.

But then you don't want face-melting lasers.

Now hold on...I can see that being useful too. Two consecutive failed face IDs? BAM!!!* face melting laser on the (probably) unauthorized person trying to access your phone.

These watches typically come with charging cables, not a docking style station that you put them in. And keeping devices at a perpetual full charge for expended periods of time is a surefire way to kill the capacity quickly.

I mean, I get a full week from my coros pace 2, with 5-6h of GPS cardio tracking (running) and 24h metrics (steps, stress, sleep, etc.) on a 310mAh battery. It takes a whopping 2h to recharge back to full, I would hate having to manage a tiny extra battery to save those 2h of not wearing my watch.

If all you want from a watch is time and alarms, you're obviously not even remotely in the demographic that any smartwatch is targeting.

Uh den ville jeg også vildt gerne se, men det er desværre prime video. Og jeg er slet ikke typen der går med træben...😅

Proxmox not conncected to internet, but is reachable on LAN

[SOLVED] Turns out I'm just a bigger moron than I thought. The MAC address of my server had accidentally been flagged in my router for black listing.

As the title says, my proxmox host is apparently not able to reach the internet anymore, not sure for how long this has been an issue, I rarely work on the host itself. It can ping other devices on my network just fine, and other devices can ping it. I can also SSH in to it and access the web interface. My VMs are connected to the internet without any issues. I don't need to access the host remotely/outside my home network, this is just for updating it etc.

I can't see the host under active devices in my router though.

I have been trying to figure why, but so far without any luck.

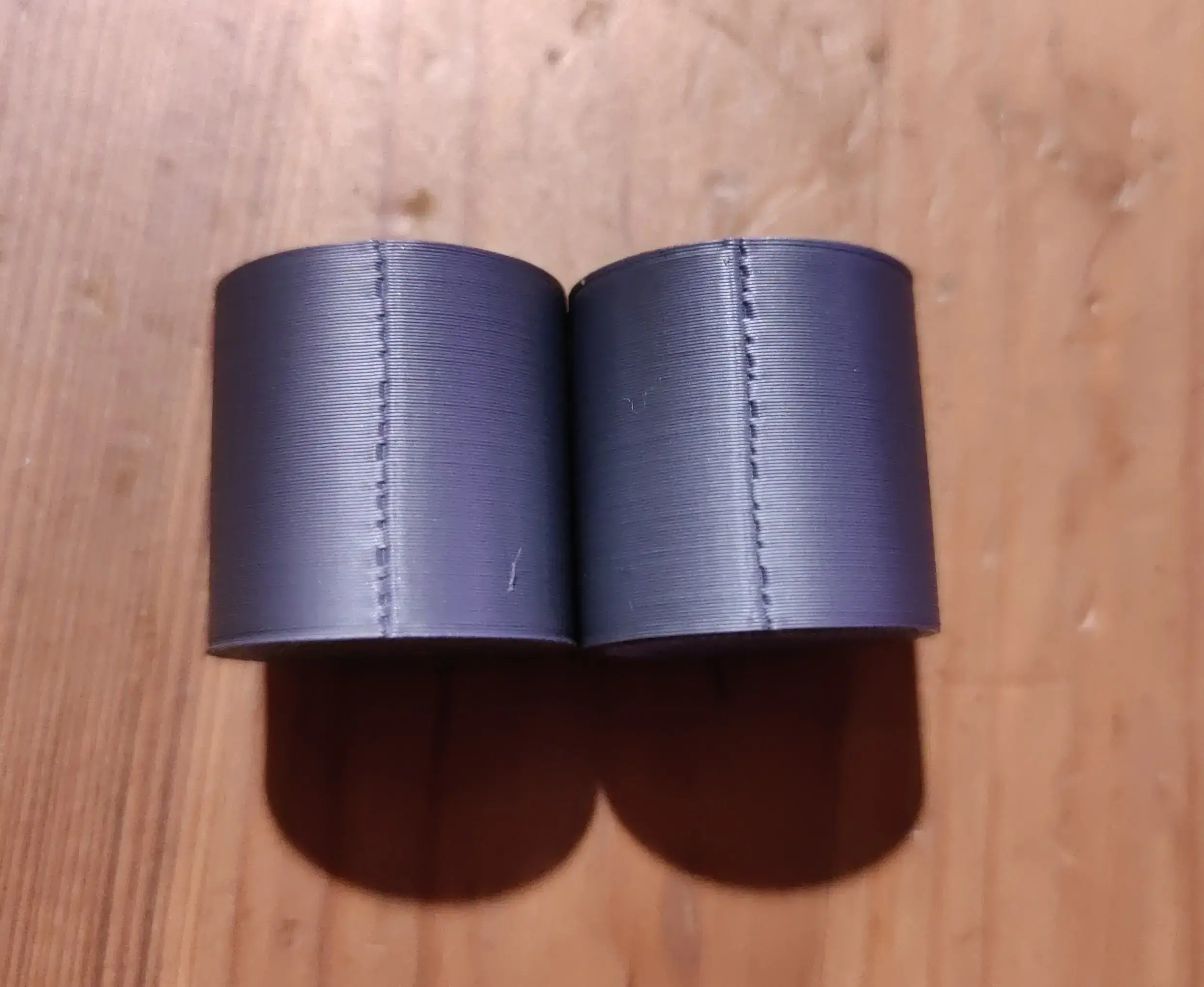

How do I fix these god-awful seams?

I have trouble fixing the terrible seams I'm getting. I've followed Elli's print tuning guide and calibrated extruder, tuned PA (it's now 0.035) and extrusion multiplier.

I've tried adjusting both retraction length and speed, but it doesn't seem to have much impact. I'm not using "wipe on retract" or "retract on layer change", I only retract if travel distance is longer than 3mm. Retract is 0.3mm @35mm/s.

I've tried reducing PA smooth time too, but this also doesn't seem to have a noticable impact.

I've tried reducing seam gap from the default 10% in Orca all the way down to 0%, but the bad seams persist.

I've tried with "wipe on loops" both disabled and enabled with no difference.

I've tried with both arachne and classic wall generator, no difference.

I've tried different wall orders, inner/outer, inner/outer/inner and outer/inner, all with the same bad seams.

Filament in the picture is matte PLA, it is without doubt dry and generally prints well aside from the seams. It's sto

Linear rail mod on Anycubic Kobra 2

I've been contemplating switching the rods that my X and Y axis travel on to linear rails instead. The current hardware is double SS rods with SG15 bearings, with an eccentric nut to adjust tension on the rods.

Unfortunately these rods are not evenly spaced on my Y-axis. They're closer together at the back than at the front, deviating with 0.5mm. So the rollers are either too tight at the front, or too loose at the back, meaning the bed wobbles a bit when using the front of the bed, or skips layers due to higher resistance on the rollers when using the back of the bed. I could lower the movement speed, but I would rather fix the actual cause of the issue.

I have some suspicion that the rollers are also not rolling smoothly on the rods and sometimes slip/skip on them instead.

And then I came across the Voron switchwire and Ender3-to-switchwire conversions. Now I'm not really willing to fully rebuild the printer as a switchwire, but changing to linear rails on Y and X axes is not a m

Any tip for printing TPU?

I've been trying to print some things in TPU, using a fairly soft 85A TPU, and I keep having under extrusion.

I've already reduced speeds to max 25mm/s, and reduced retraction. My printer uses a direct drive extruder, and as far as I can tell, it's grabbing the filament just fine. I'm printing at 240°C, using my default 0.4mm volcano CHT brass nozzle.

Voron 2.4R2 vs. Trident

I'm looking to expand my printer lineup, and have been looking at kits from magic phoenix for both the Voron Trident and the v2.4R2.

Is there any real benefit to one over the other, or is it more a preference thing?

Edit: if anyone know of other kits, preferably available in the EU, I would also like to take a look at those.

Stuttering when printing PETG

I tried printing with PETG yesterday, and I noticed that it intermittently stops moving during the print for a few seconds. It doesn't throw an error or anything, just stops and then after a few seconds resumes as if nothing happened. But this creates huge blobs where it stops. It only happens when printing PETG, not PLA. Could this be caused by a filament setting in my slicer? I'm using prusa slicer. I inspected the gcode and there are no stops, pauses or color changes etc. in it. The behaviour happens both when printing from octoprint and directly from SD card.

Edit: these random intermittent stops are 10-20 seconds long, causing massive blobs from oozing filament.

Edit 2: so it seems to not actually be a PETG specific issue, but rather a model size/speed issue. I can get it running without stops if I just reduce print speed. When I crank speed to 100% I start getting these weird 10-20 second long stops.

So I'm overloading the controller with a lot of gcode commands in rapid succ

Why do we still use stepper motors?

Why are 3D printers still stuck on stepper motors? Why haven't we transitioned to servo motors with encoder feedback for positioning?

Is it just too cost prohibitive for the consumer-level? We would be able to print a lot faster and more accurately if we had position feedback on the axes. Instead we just rely blindly on the stepper not skipping any steps when we tell it to move, hoping for the best.

Printer not moving to expected coordinate

I have run in to a strange issue where the X and Y axes don't move to the specified coordinate beyond a certain range.

The steps/unit are calibrated, when i tell an axis to move to position 100mm (using G0 or G1 command manually), it moves to position 100mm, this goes for both X and Y axis...but it seems like it hits a software-stop when i tell it to move beyond 225mm on both of them, which is weird since build plate is 230mmx230mm, and nozzle wipe-pad and Z-offset calibration are located at Y position 240mm-245mm.

The stepper just stops at 225mm even if i tell it to move beyond this point, and if i tell it to move back to 0mm, it positions itself correctly at the starting point. It doesn't sound like any skipping on the belt or the stepper itself is happening, it's completely silent but just stops. I can easily move the bed and print-head beyond this point by hand, and i can't feel any noticeable increased resistance in the movement.

The odd thing is, that this worked just fine a

Linear advance calibration

I'm trying to calibrate linear advance on my anycubic kobra 2, using the guide in this video. I have calibrated my E-steps and flow rate for the extruder, and get the expected 100mm extrusion and expected wall thickness...so far, so good.

When i attempt the LA calibration to find my K value, i get the result shown in the image, with a serious deterioration of line quality when LA is enabled (K>0), and it seemingly gets worse as the K value increases.

I have used the tool from marlinfw.org to generate the g-code for testing K values.

Anycubic Kobra 2 wipe functionality

I'm using an Anycubic Kobra 2 printer, it has a nice rubber pad at the back of the plate, which i assume is for wiping the nozze? However the printer profile Anycubic provides for prusa slicer doesn't use it at all, and actually has a fair amount of oozing because it heats the extruder first (which it then doesn't wipe away). So i decided i would add it myself. I'm completely new 3D printing, having only had the printer for a little over a week, so my solution may be a bit rough around the edges.

undefined

################ Start G-code with nozzle wipe and purge in back-left corner ################

G90 ; use absolute coordinates

M83 ; set extruder to relative mode

M140 S[first_layer_bed_temperature] ; set bed temp

G28 ; home all axes

G1 Z2 ; raise nozzle to 2mm

G92 E0 ; res

storing of filamenter bewteen prints

How long do you have filament sitting "in the open"? I mostly print with a single filament roll at a time, and just leave it on the printer. A 1kg roll lasts me several weeks. For long time storage I keep it in an air tight box with disiccant pouches.

But how long can I let it sit before I should start storing it with disiccant and/or drying the filament before use?

Anycubic custom Gcode

I wanted to print a temperature tower, but the custom Gcode entered in prusa slicer doesn't seem to actually change the temperature of the nozzle? It just uses the temperature that's configured on "other layers" under the filament tab.

I'm attempting gaaZolee's temperature tower, using the custom Gcode supplied with it, in the "before layer change" part of custom Gcode in prusa slicer.

beginner issues, how to identify cause?

I just assembled my new Anycubic Kobra 2, performed an auto level and tried to print the 30min benchy file they include on the micro SD card that it ships with. No other modifications of adjustments made. It printed in pretty much exactly the 30min the advertised.

It's think it did OK, but with obvious issues. Since I'm new to the hobby I don't know exactly what to expect and how to identify print quality issues.

My benchy looks like this:

MitID på Lineage OS?

Når man nu har smidt Lineage OS på sin gamle android telefon (oneplus 9pro), så vil MitID jo ikke rigtig lege med fordi bootloaderen ikke er låst. Findes der et fix så jeg ikke skal have en anden telefon med stock ROM for at bruge det? Hvis jeg låser bootloaderen igen så havner den bare i et bootloop :/

Edit: forslaget fra humanplayer2 virkede, rettede fire tekststrenge i build.prop på telefonen fra "Lineage"/"userdebug" til "Linage"/"user" og voila! så virker mitID.

Recap fra reddit linket nedenunder, så vi har det på feddit.dk også.

Hvis man slår "Rooted debugging" til under Developer Options kan man gøre:

undefined

adb root

adb pull /system/build.prop

Redigér filen på computeren, udskift følgende tekststrenge:

undefined

"dev-keys"/“test-keys” til “release-keys”

“userdebug” til “user”

“lineage” til f.eks. "linage"

overfør build.prop tilbage til telefonen

undefined

adb remount

adb push build.prop /system/build.prop

genstart telefonen

undefined

adb reboot

*slet cache

issues with QbitTorrent stalled torrents

I am just getting back my sea legs, but apparently they're pretty shaky because I can't get my ubuntu torrent (no seriously, it is) to download. It never starts downloading and is stuck in "stalled". I've tried a number of things, but even with default settings it isn't starting. I'm using proton VPN on Linux Mint, but even with the VPN disabled it doesn't work.

last time I torrented was probably 15 years ago.

EDIT: i managed to get it working. As expected it was a Qbit config issue. First issue was a port forwarding issue. second one was the interface i connected it to. Apparently the interface named something with "vpn" is not the correct one to bind Qbit to, its a dummy created by the VPN that doesn't work. I had to select one named "tun0". If i just selected the regular physical interface I had IP leaks with the VPN enabled.

Bypassing phone number requirements?

Are there any ways to avoid handing over your real phone number, besides having an extra SIM? Lots of places/services want SMS verification, but i rarely want to hand out my actual phone number.

Tamper texture/pattern...does it matter?

I accidentally bought a tamper with a textured surface instead of just a smooth surface. Is one better than the other?

A running haiku

I have been running for a few years, but today I had an interesting first experience while out on the road. Here's a little haiku I cooked up while returning home.

I run far and hard

Today I had a new first

Never trust the fart

Brew time for single, double, triple shots?

Do you aim to keep the brew time around 30sec regardless of shot size? If so, how do you go about that? Do you grind coarser? Tamp less hard?

If i keep my grind settings the same and tamp with (what feels like) the same force, my extraction time takes a lot longer when pulling a double shot (i use 16g) compared to single shot (8g), and using the same ratio.